TOPOLOGY OPTIMIZATION METHOD FOR INTEGRATED THERMAL PROTECTION STRUCTURE CONSIDERING TRANSIENT TEMPERATURE AND STRESS CONSTRAINTS

-

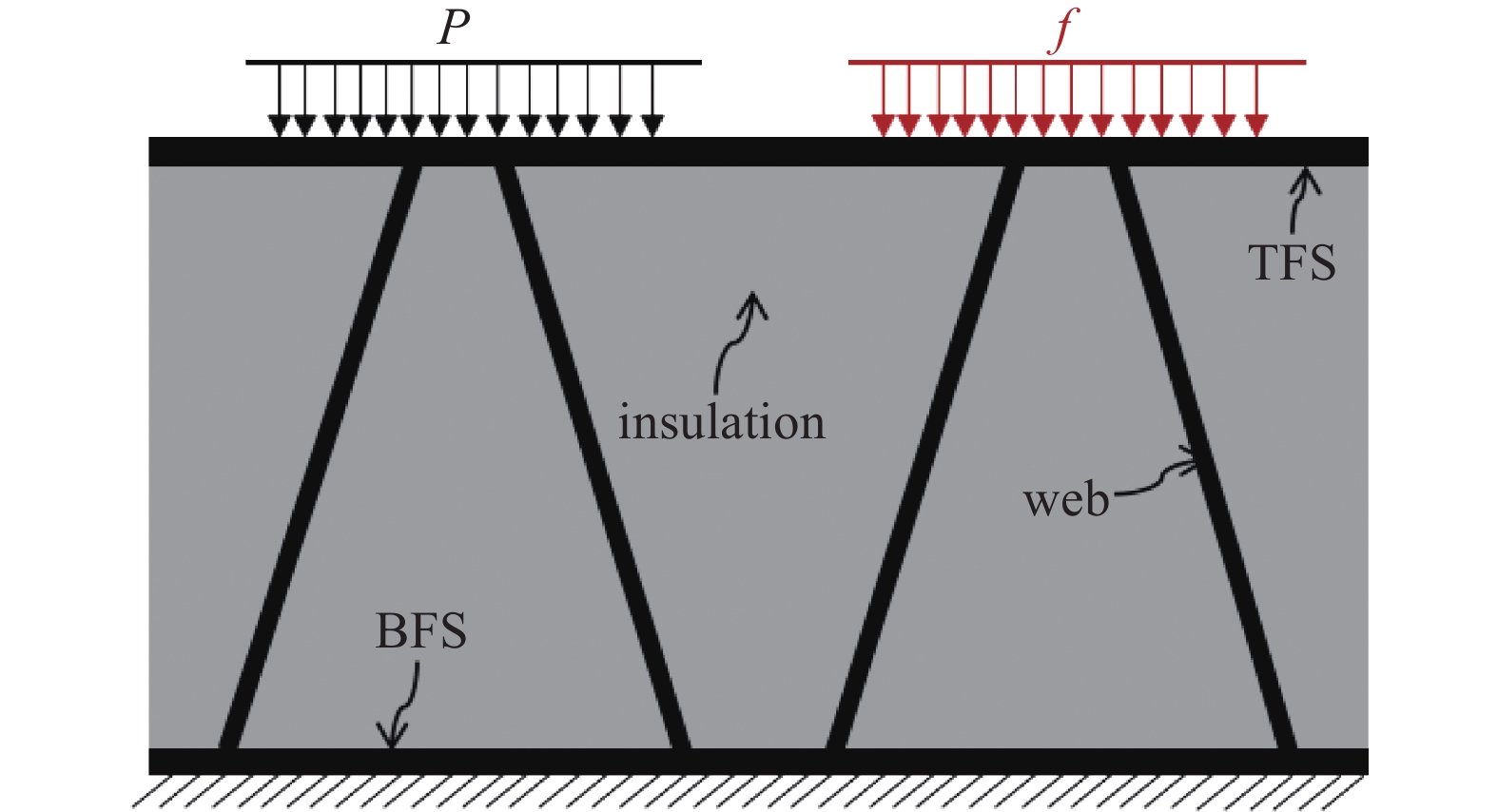

摘要: 一体化热防护结构通常处于严酷的非稳态热环境, 热载荷作用的时间效应(即瞬态热效应)明显. 为了避免瞬态热分析的巨大计算消耗, 以往的一体化热防护结构优化设计研究通常将瞬态传热等效为相同热边界条件下的稳态传热, 将稳态传热分析的温度场作为设计热载荷. 然而, 已有的研究表明稳态传热无法准确等效瞬态传热的作用效果, 瞬态热效应对结构设计结果具有重要影响. 文章研究了考虑瞬态热效应的一体化热防护结构优化设计问题, 建立一种考虑瞬态温度和应力约束的一体化热防护结构拓扑优化方法. 该方法以SIMP (solid isotropic material with penalization) 法为基础, 构建两种针对一体化热防护结构的热弹性结构拓扑优化模型: (1)考虑材料体积分数、最大应力和底面最大温度约束, 以最小化结构应变能为目标的刚度设计模型; (2)考虑最大应力和底面最大温度约束, 以最小化材料体积分数为目标的轻量化设计模型. 通过求解瞬态热力耦合方程获得结构的热力耦合静力分析结果; 通过响应量在空间和时间域的凝聚积分函数表征结构响应在时域内的最大值, 并以此构建相应的约束和目标函数; 采用伴随法推导约束和目标函数的灵敏度表达式. 通过3个数值算例验证了本方法的有效性. 数值算例结果表明, 在瞬态传热条件下, 本方法能够准确反映瞬态热效应对一体化热防护结构设计结果的影响; 相比于基于稳态热分析的设计结果, 考虑瞬态热效应的设计结果具有更优的性能.Abstract: The integrated thermal protection structure is usually in a severe unstable thermal environment, and the time effect of thermal load, namely transient thermal effect, is obvious. In order to avoid huge calculation consumption of transient thermal analysis, previous optimization design studies of integrated thermal protection structures usually equivalent transient heat transfer to steady-state heat transfer under the same thermal boundary conditions, and take the temperature field of steady-state heat transfer analysis as the design thermal load. However, previous studies have shown that the steady-state heat transfer cannot accurately equivalent the effect of transient heat transfer, and the transient thermal effect has an important influence on the structural design results. In this paper, the optimization design problem of integrated thermal protection structure considering transient thermal effect is studied, and a topology optimization method of integrated thermal protection structure considering transient temperature and stress constraints is established. Based on the solid isotropic material with penalization (SIMP) method, two kinds of topology optimization models for integrated thermal protection structures are constructed: (1) the stiffness design model taking minimizing the structural strain energy as objective function, considering material volume fraction, maximum stress and maximum bottom-face temperature constraints; (2) the strength design model taking minimizing material volume fraction as objective function, considering maximum stress and maximum bottom-face temperature constraints. By solving the transient thermodynamic coupling equation, the thermodynamic coupling static analysis results of the structure are obtained. The maximum value of structural response in time domain is represented by the condensed integral function in space and time domains, which was taken as constraint and objective functions. The sensitivity expressions of objective function and constraint functions are derived by adjoint method. The effectiveness of the proposed method is verified by three numerical results. Numerical examples showed that the proposed method could accurately reflect the influence of transient thermal effects on the design results of integrated thermal protection structures under the condition of transient heat transfer. Compared with the design results based on steady-state thermal analysis, the design results considering transient thermal effects were significantly improved.

-

表 1 所用材料的属性列表

Table 1. Lists the properties of the materials used

Density/

(kg·m−1)Young’s

modulus/

GPaPoisson’s

ratioThermal

conductivity/

(W·m−1·°C−1)Heat

capacity/

(J·°C−1·kg−1)CTE/

K−1mat-1 4620 96 0.36 21.9 522 ${\text{9} }{\text{.4} } \times {\text{1} }{ {\text{0} }^{ {{-6} } } }$ mat-2 50 0.0001 0.36 0.15 942 0 表 2 优化结果瞬态热力耦合分析

Table 2. Transient thermodynamic coupling analysis of optimization results

Performance Method tf = 1800 s tf = 2400 s tf = 3600 s strain energy method 1 50.23 51.86 53.52 proposed method 45.17 46.95 48.57 σMax/MPa method 1 50.1 50.5 48.6 proposed method 46.0 46.0 46.0 TBFSMax/°C method 1 68.6 98.2 159.8 proposed method 59.8 84.4 137.9 表 3 优化结果瞬态热力耦合分析

Table 3. Transient thermodynamic coupling analysis of optimization results

Performance Method tf = 1800 s tf = 2400 s tf = 3600 s volume fraction method 1 0.232 0.232 0.232 proposed method 0.179 0.216 0.251 σMax/MPa method 1 42.78 48.1 52.6 proposed method 46.0 46.0 46.0 TBFSMax/°C method 1 45.55 66.2 108.5 proposed method 56.64 76.0 102.7 表 4 优化结果瞬态热力耦合分析

Table 4. Transient thermodynamic coupling analysis of optimization results

Strain energy σMax/MPa TBFSMax/°C method 1 26.45 50.50 55.1 proposed method 25.31 46.0 58.4 -

[1] 杨强, 解维华, 彭祖军等. 热防护设计分析技术发展中的新概念与新趋势. 航空学报, 2015, 36(9): 2981-2991 (Yang Qiang, Xie Weihua, Peng Zhujun, et al. New concepts and trends in development of thermal protection design and analysis technology. Acta Aeronautica et Astronautica Sinica, 2015, 36(9): 2981-2991 (in Chinese) doi: 10.7527/S1000-6893.2015.0137Yang Q, Xie W H, Peng Z J, et al. New concepts and trends in development of thermal protection design and analysis technology [J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(9): 2981-2991. (in Chinese) doi: 10.7527/S1000-6893.2015.0137 [2] 解维华, 霍施宇, 杨强等. 新型一体化热防护系统热力分析与试验研究. 航空学报, 2013, 34(9): 2169-2176 (Xie Weihua, Huo Shiyu, Yang Qiang, et al. Thermal-mechanical analysis and test study of a new integrated thermal protection system. Acta Aeronautica et Astronautica Sinica, 2013, 34(9): 2169-2176 (in Chinese)Xie W H, Huo S Y, Yang Q, et al. Thermal-mechanical analysis and test study of a new integrated thermal protection system [J]. Acta Aeronautica et Astronautica Sinica, 2013, 34(9): 2169-2176. (in Chinese) [3] Zhao SY, Li JJ, Zhang CX, et al. Thermo-structural optimization of integrated thermal protection panels with one-layer and two-layer corrugated cores based on simulated annealing algorithm. Structural and Multidisciplinary Optimization, 2015, 51(2): 479-494 doi: 10.1007/s00158-014-1137-4 [4] Xie G, Wang Q, Sunden B, et al. Thermomechanical optimization of lightweight thermal protection system under aerodynamic heating. Applied Thermal Engineering, 2013, 59(1-2): 425-434 doi: 10.1016/j.applthermaleng.2013.06.002 [5] Wei K, Cheng X, Mo F, et al. Design and analysis of integrated thermal protection system based on lightweight C/SiC pyramidal lattice core sandwich panel. Materials & Design, 2016, 111: 435-444 [6] Chen Y, Tao Y, Xu B, et al. Assessment of thermal-mechanical performance with structural efficiency concept on design of lattice-core thermal protection system. Applied thermal engineering, 2018, 143: 200-208 doi: 10.1016/j.applthermaleng.2018.07.097 [7] Gogu C, Bapanapalli SK, Haftka RT, et al. Comparison of materials for integrated thermal protection systems for spacecraft reentry. Journal of Spacecraft and Rockets, 2009, 46(3): 501-513 doi: 10.2514/1.35669 [8] 吴书豪, 张永存, 刘书田. 一种考虑瞬态效应的散热结构导热路径设计的拓扑优化模型. 计算力学学报, 2018, 35(5): 547-551 (Wu Shuhao, Zhang Yongcun, Liu Shutian. A topology optimization model for conducting paths design of cooling structures considering transient effect. Chinese Journal of Computional Mechanics, 2018, 35(5): 547-551 (in Chinese)Wu S H, Zhang Y C, Liu S T. A topology optimization model for conducting paths design of cooling structures considering transient effect [J]. Chinese Journal of Computional Mechanics, 2018, 35(05): 547-551. (in Chinese)) [9] Bendsoe MP. Optimal shape design as a material distribution problem. Structural Optimization, 1989, 1(4): 193-202 doi: 10.1007/BF01650949 [10] Yang Q, Meng S, Xie W, et al. Effective mitigation of the thermal short and expansion mismatch effects of an integrated thermal protection system through topology optimization. Composites, Part B: Engineering, 2017, 118: 149-157 [11] Yang Q, Gao B, Xu Z, et al. Topology optimization for integrated thermal protection systems considering thermo-mechanical constraints. Applied Thermal Engineering, 2019, 150: 995-1001 doi: 10.1016/j.applthermaleng.2019.01.067 [12] Xu Q, Li S, Meng Y. Optimization and re-design of integrated thermal protection systems considering thermo-mechanical performance. Applied Sciences, 2021, 11(15): 6916 doi: 10.3390/app11156916 [13] Zhao SY, Li JJ, He XD. Comparison of thermo-structural responses for integrated thermal protection panels with different corrugated core configurations. Journal of Harbin Institute of Technology, 2013, 20(6): 21-28 [14] Xu JF. Thermal impact resistance of integrated thermal protection system of space vehicles. Advanced Materials Research, 2015, 1091: 103-108 doi: 10.4028/www.scientific.net/AMR.1091.103 [15] Meng S, Yang Q, Xie W, et al. Structure redesign of the integrated thermal protection system and fuzzy performance evaluation. AIAA Journal, 2016, 54(11): 1-10 [16] Wei K, Wang KY, Cheng XM, et al. Structural and thermal analysis of integrated thermal protection systems with C/SiC composite cellular core sandwich panels. Applied Thermal Engineering: Design, Processes, Equipment, Economics, 2018, 131: 209-220 [17] Xu Y, Xu N, Zhang W, et al. A multi-layer integrated thermal protection system with C/SiC composite and Ti alloy lattice sandwich. Composite Structures, 2019, 230: 111507 doi: 10.1016/j.compstruct.2019.111507 [18] Li Y, Zhang L, He R, et al. Integrated thermal protection system based on c/sic composite corrugated core sandwich plane structure. Aerospace Science and Technology, 2019, 91: 607-616 doi: 10.1016/j.ast.2019.05.048 [19] K Lin, K Hu, Gu D. Metallic integrated thermal protection structures inspired by the norway spruce stem: design, numerical simulation and selective laser melting fabrication. Optics and Laser Technology, 2019, 115: 9-19 doi: 10.1016/j.optlastec.2019.02.003 [20] Xu N, Xu Y, Zhang W, et al. Design and analysis of multi-layer integrated thermal protection system based on ceramic matrix composite and titanium alloy lattice sandwich. IOP Conference Series. Materials Science and Engineering, 2019, 531(1): 12059 doi: 10.1088/1757-899X/531/1/012059 [21] Shi S, Wang Y, Yan L, et al. Coupled ablation and thermal behavior of an all-composite structurally integrated thermal protection system: fabrication and modeling. Composite Structures, 2020, 251: 112623 doi: 10.1016/j.compstruct.2020.112623 [22] Cao C, Wang R, Xing X, et al. Performance improvement of integrated thermal protection system using shaped-stabilized composite phase change material. Applied Thermal Engineering, 2020, 164: 114529 doi: 10.1016/j.applthermaleng.2019.114529 [23] Xie G, Wang C, Ji T, et al. Investigation on thermal and thermomechanical performances of actively cooled corrugated sandwich structures. Applied Thermal Engineering, 2016, 103: 660-669 doi: 10.1016/j.applthermaleng.2016.04.117 [24] Zhuang C, Xiong Z. A global heat compliance measure based topology optimization for the transient heat conduction problem. Numerical Heat Transfer, Part B: Fundamentals, 2014, 65(5): 445-471 doi: 10.1080/10407790.2013.873309 [25] Zhuang CG, Xiong ZH. Temperature-constrained topology optimization of transient heat conduction problems. Numerical Heat Transfer, Part B:Fundamentals, 2015, 68(4): 366-385 doi: 10.1080/10407790.2015.1033306 [26] Long K, Wang X, Gu X. Multi-material topology optimization for the transient heat conduction problem using a sequential quadratic programming algorithm. Engineering Optimization, 2018, 50(12): 2091-2107 doi: 10.1080/0305215X.2017.1417401 [27] Wu SH, Zhang YC, Liu ST. Topology optimization for minimizing the maximum temperature of transient heat conduction structure. Structural and Multidisciplinary Optimization, 2019, 60(1): 69-82 doi: 10.1007/s00158-019-02196-9 [28] Hyun J, Kim HA. Level-set topology optimization for effective control of transient conductive heat response using eigenvalue. International Journal of Heat and Mass Transfer, 2019, 176: 121374 [29] Wu SH, Zhang YC, Liu ST. Transient thermal dissipation efficiency based method for topology optimization of transient heat conduction structures. International Journal of Heat and Mass Transfer, 2021, 170(3): 121004 [30] Zhang S, Yin J, Liu Y, et al. Multiobjective structure topology optimization of wind turbine brake pads considering thermal-structural coupling and brake vibration. Mathematical Problems in Engineering, 2018, 2018: 1-10 [31] Leader MK, Kennedy G. Thermoelastic topology optimization using steady-state and transient analysis for stress and thermal performance//AIAA Scitech, 2021 Forum [32] Hu SB, Chen LP, Zhang Y, et al. Design 3D thermo-mechanical structures with multidisciplinary topology optimization. Advanced Materials Research, 2012, 466-467: 1212-1216 doi: 10.4028/www.scientific.net/AMR.466-467.1212 [33] Zhang W, Yang J, Xu Y, et al. Topology optimization of thermoelastic structures: mean compliance minimization or elastic strain energy minimization. Structural & Multidisciplinary Optimization, 2013, 49(3): 417-429 [34] Deaton JD, Grandhi RV. Topology optimization of thermal structures with stress constraints. Schizophrenia Research, 2013, 136(2): 259-263 -

下载:

下载: